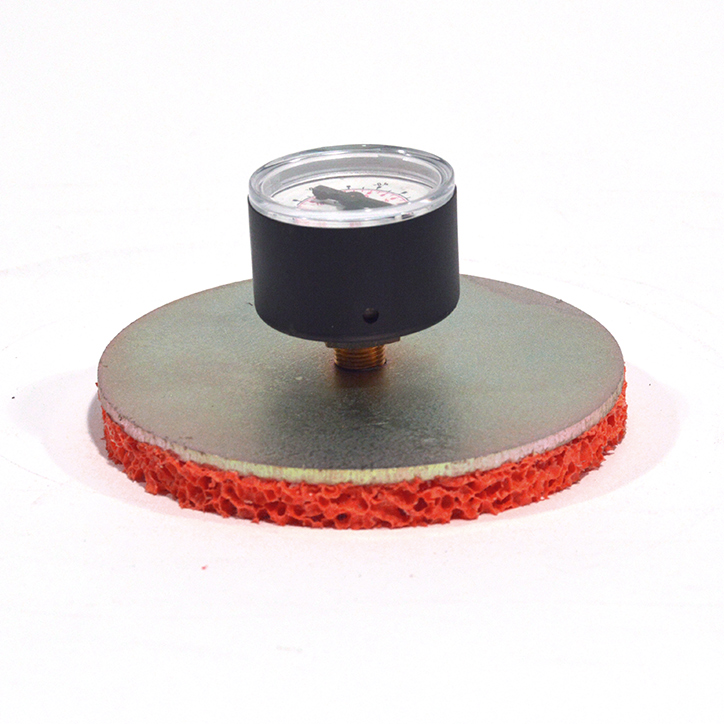

Vacuum ether, test device for machine troubleshooting

Vacuum ether, test device for machine troubleshooting. In 95% of the cases when a machine does not work as it should, it is due to a leak. With the help of the vacuum meter, you can quickly and easily search for the leak. Start by measuring the negative pressure directly against the vacuum pump, the negative pressure should be between 0.55-0.6 bar. Then measure the negative pressure against the filter cap to see if the filter is tight. Then measure the negative pressure in each vacuum hose to finish by measuring directly against the control panel. If the negative pressure is below 0.55 bar directly against the vacuum pump, there is something wrong with it. If the negative pressure is below 0.55 bar against the filter cover, your filter is clogged. If the negative pressure is below 0.55 bar in any of the hoses, the hose is leaking or clogged. If any of the hoses are leaking, tape with tissue tape type: 700PS618. ATTENTION! no other tape may be used to temporarily fix our vacuum hoses. Replace damaged hose promptly.

CONTACT PERSONS

For more information, please contact one of our employees below or fill out the contact form.

Do you want to know more

Do you want to know more about Pritec Maskin's products? Fill out the form and we'll get in touch.